Expertise and Manufacturing Capabilities

At Frontier Swiss, we specialize in manufacturing high-quality, precision screw machine parts, focusing on small, intricate components with diameters less than 1 inch. Our state-of-the-art facility, equipped with Tsugami Swiss-style screw machines, allows us to consistently hold the tightest tolerances, ensuring exceptional accuracy and timely delivery.

Tight Tolerances

Our advanced machining capabilities enable us to achieve precise tolerances, exemplified by:

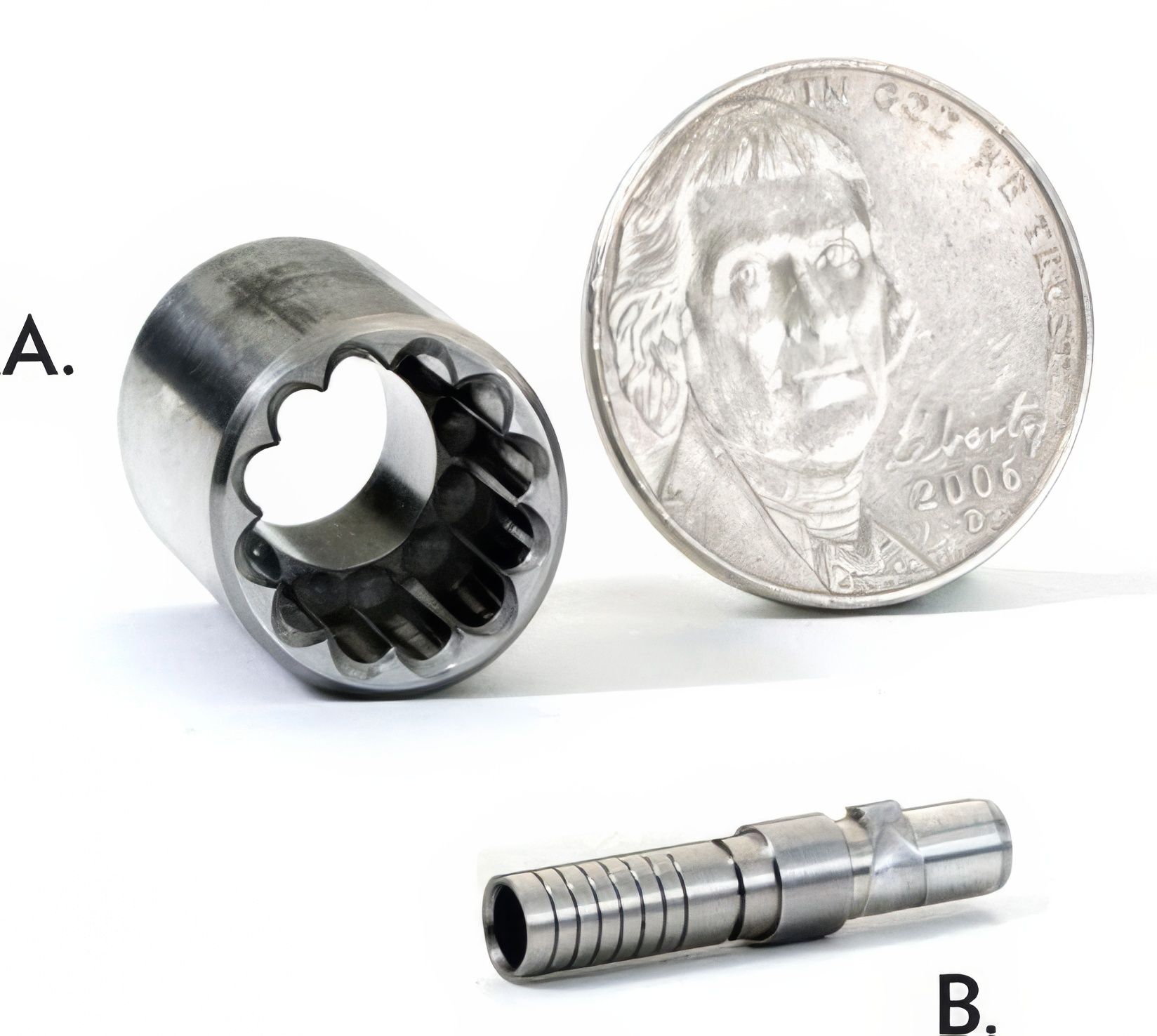

- ID Hole Precision: Manufacturing parts with an internal diameter tolerance of ±0.0002 inches, including off-center face milling to produce splines.

- Complex ID Profiling: Producing components with a total internal diameter tolerance of 0.0003 inches, featuring intricate ID profiling and milled keys requiring C-axis contouring

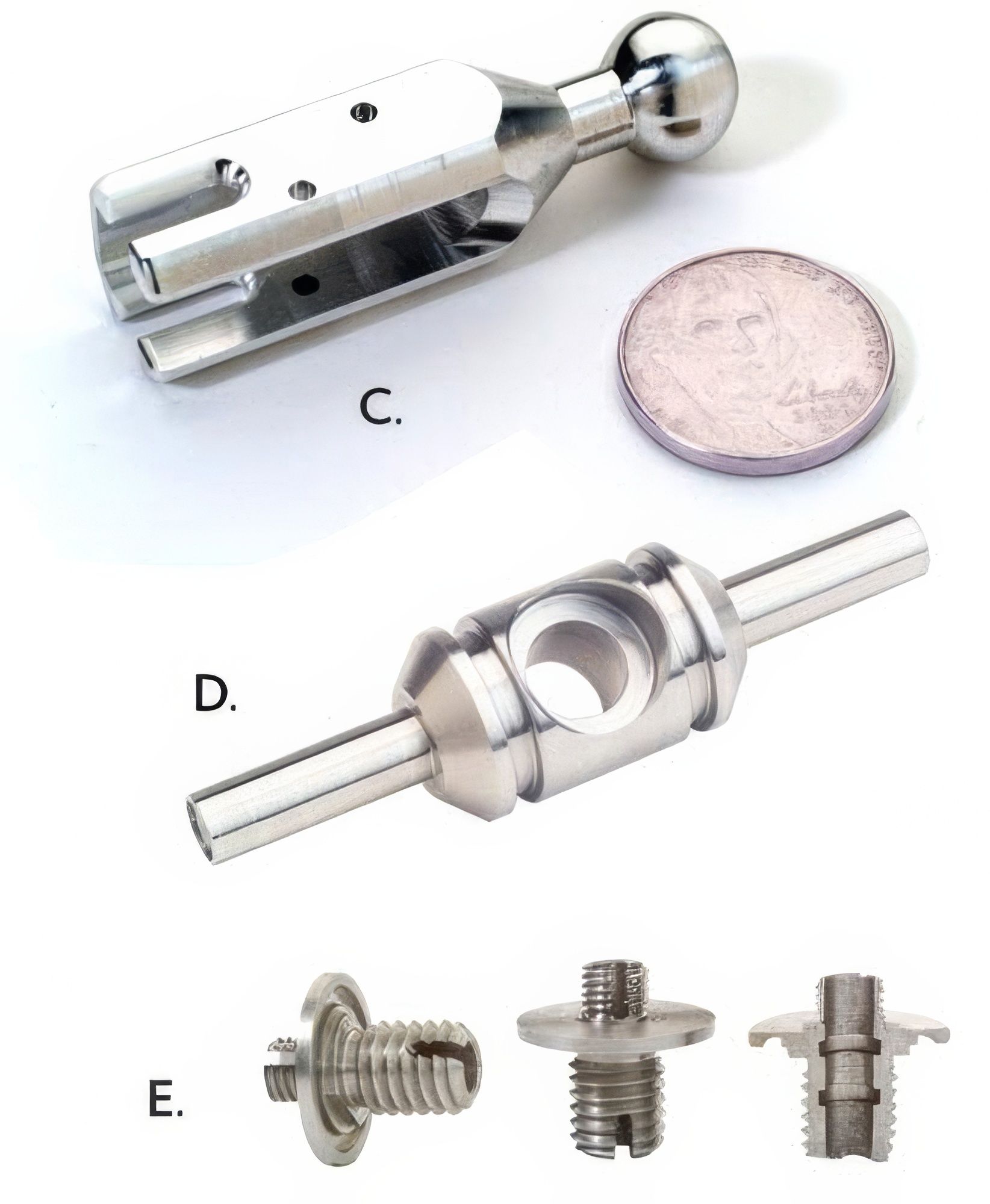

(Figure C)This part required a variety of milling, contouring, and off-center drilling and tapping.

(Figure D)

This part demonstrates our ability to cross-drill a hole, mill a counter-bore and then deburr the counter-bore with C-axis contouring in 17-4 Stainless.

(Figure E)This part displays our capability to produce ID contours and grooves, a face groove, and a keyway on each end of the part.

Complex Machining - milling, contouring, off-center drilling

Our advanced machining capabilities enable us to achieve precise tolerances, exemplified by:

- ID Hole Precision: Manufacturing parts with an internal diameter tolerance of ±0.0002 inches, including off-center face milling to produce splines.

- Complex ID Profiling: Producing components with a total internal diameter tolerance of 0.0003 inches, featuring intricate ID profiling and milled keys requiring C-axis contouring

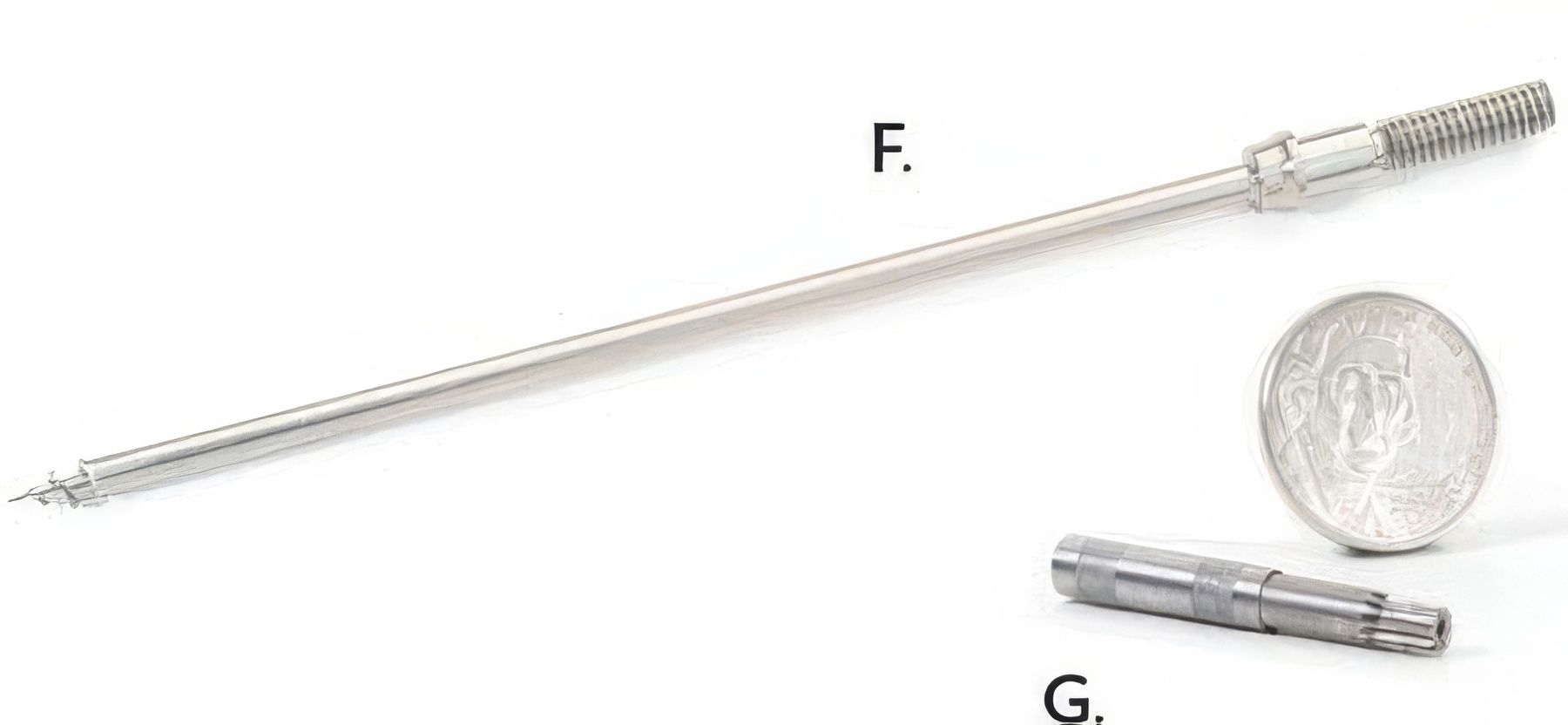

Long Parts

Our expertise extends to manufacturing parts with high length-to-diameter ratios, including:

- Medical Components: Long medical parts requiring C-axis milling to produce features like auger tips.

- Thin Parts with Milled Gears: Long, thin parts featuring milled gears, such as a 12-tooth gear at the end.

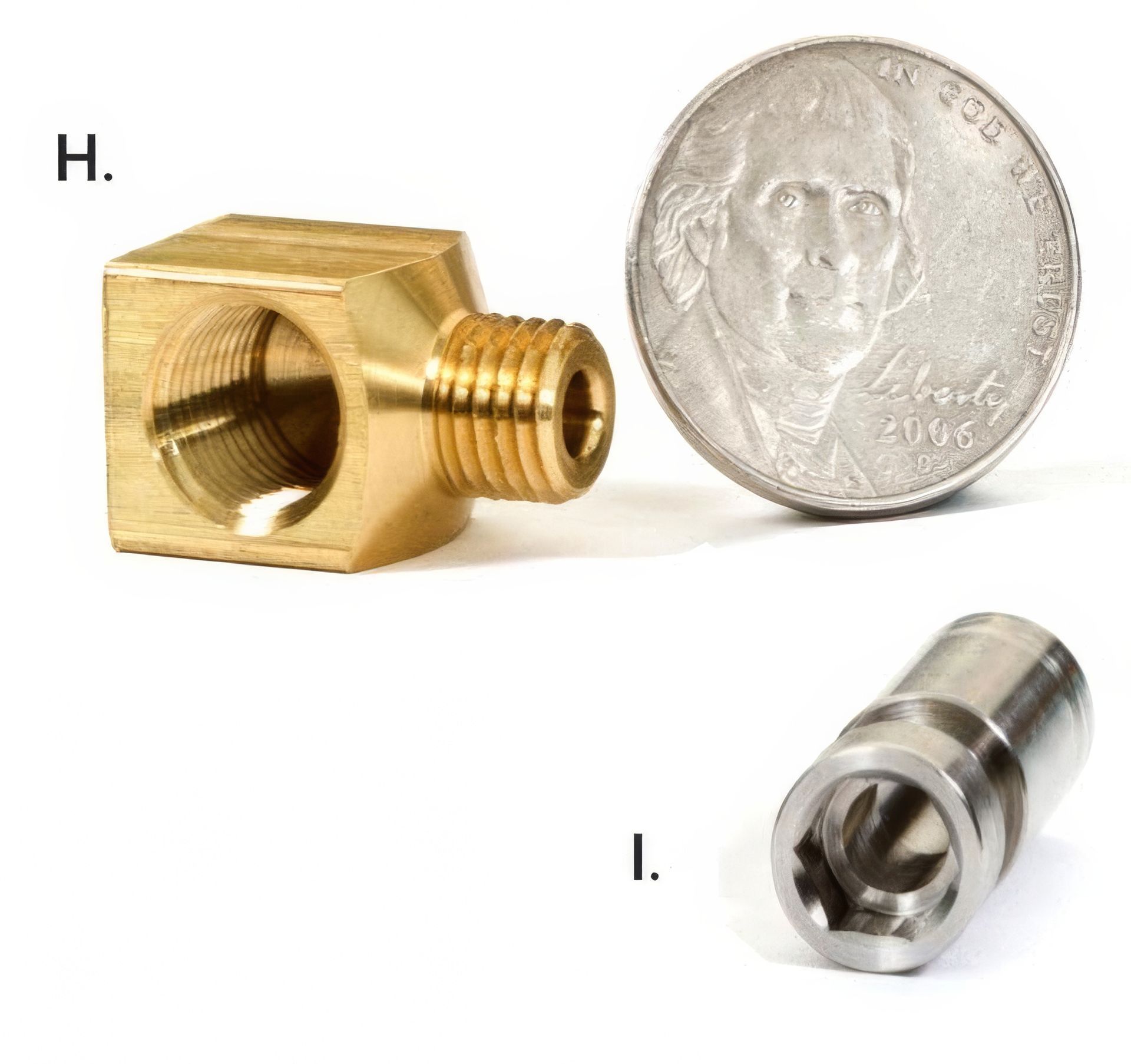

(Figure H)

This part shows a square stock with a cross-tapped pipe thread.

(Figure I)

This part demonstrates our ability to cross-drill a hole, mill a counter-bore and then deburr the counter-bore with C-axis contouring in 17-4 Stainless.

Complete Machining

We pride ourselves on delivering components that are complete upon exiting the machine, eliminating the need for secondary operations. This includes:

- Square Stock with Cross-Tapped Pipe Threads: Parts machined from square stock with cross-tapped pipe threads.

- Internal Hex Broaching: Components featuring internal hex shapes broached directly on our machines.